- 1 FREE ticket gives you access to 4 exhibitions and the conference

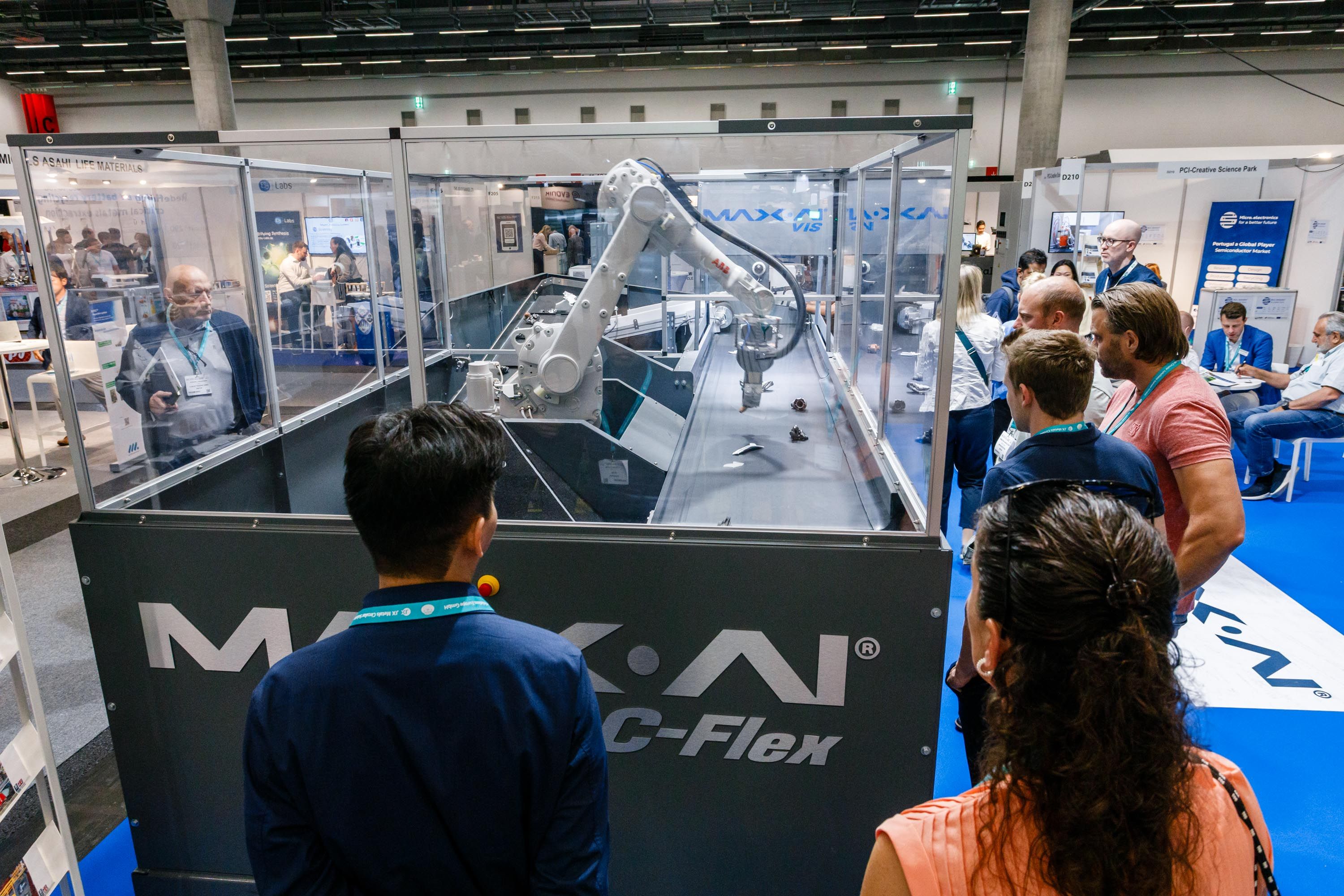

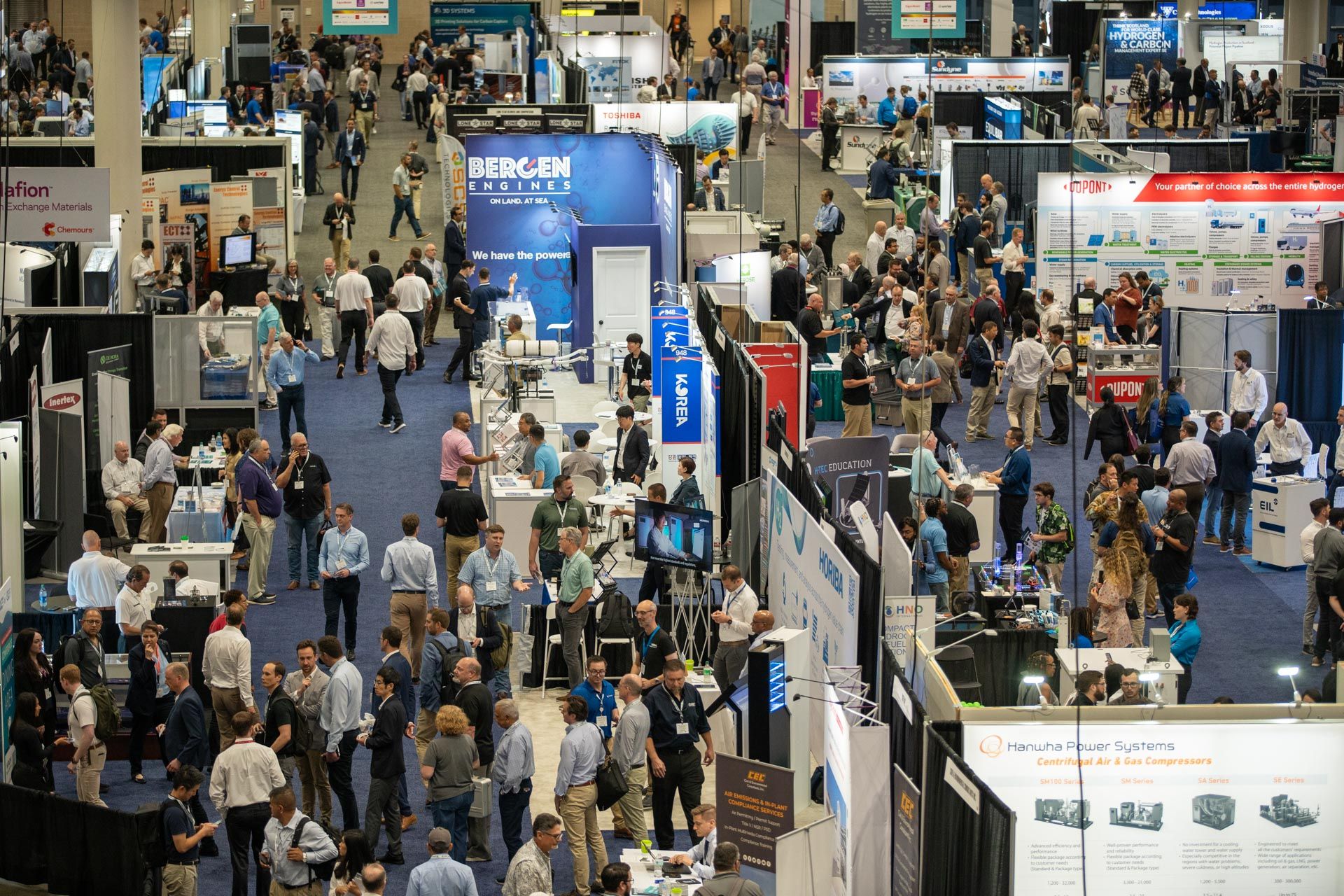

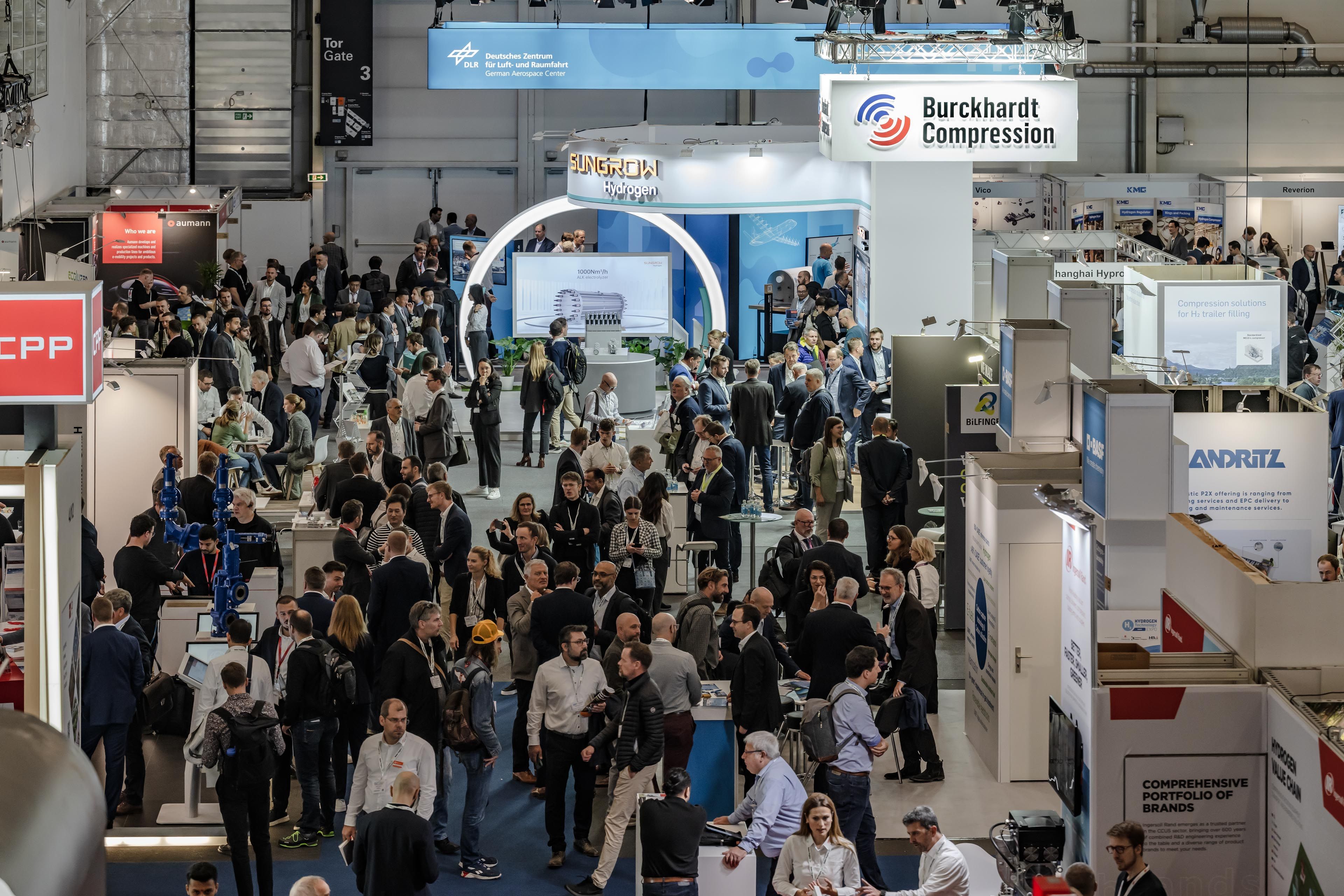

- Exhibit at the show and position your brand at the forefront of innovation

- Demonstrate your latest products and solutions to a captivated audience

- Connect with C-level executives, tech innovators, and industry experts

- Keynote speakers from around the world will tackle the hottest topics facing our industries

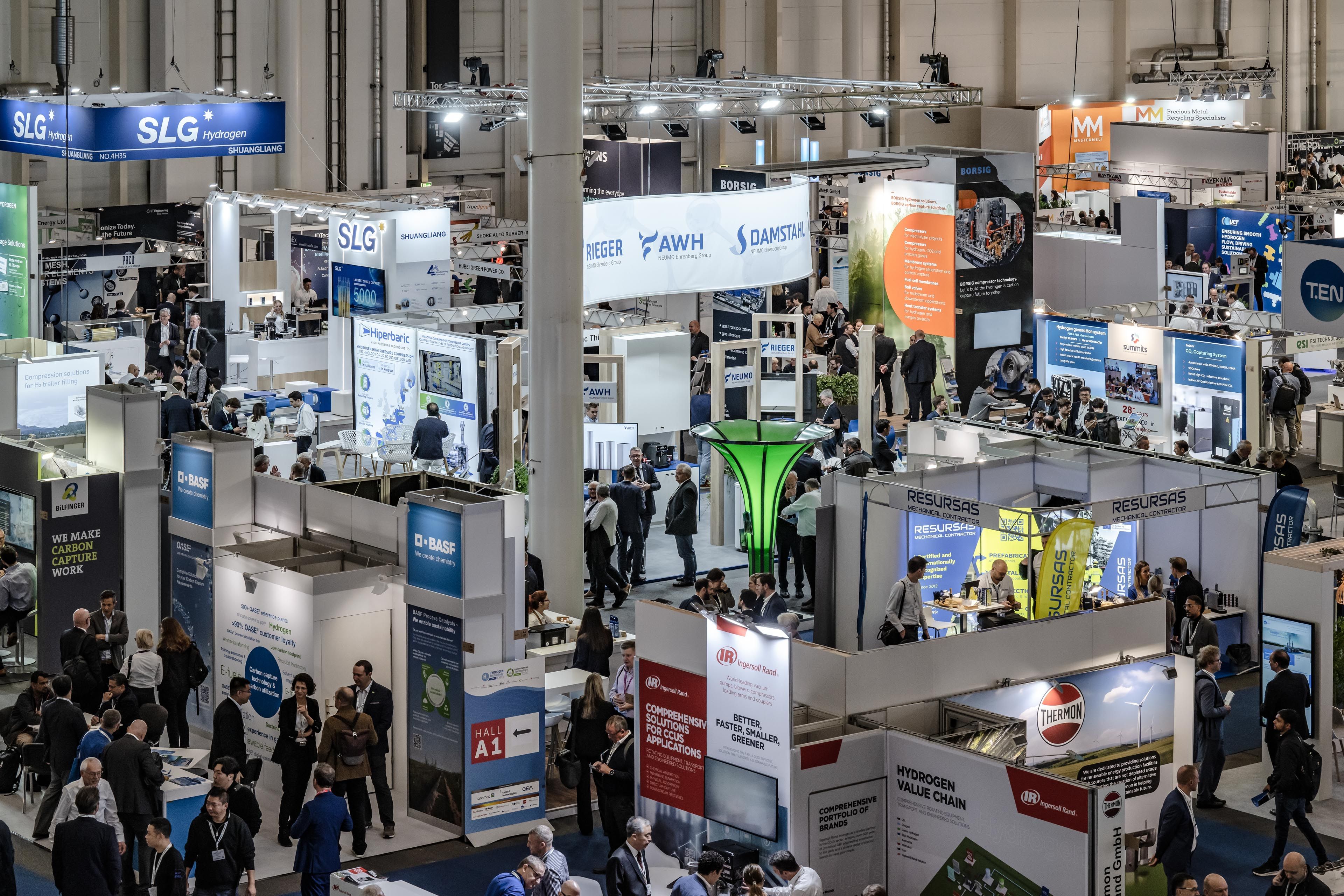

Over 400 Exhibitors

The exhibition is the perfect place opportunity to showcase your company in front of a highly targeted audience.

)

)

)

)

)

)

)

)

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Eldan-Recycling-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/DOWA-HD-Europe-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Zato-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Recycleye-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Qiansen-Machinery-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/ECOWES-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Albert-Hoffmann-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Jacomij-Electronics-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Jacomij-Metalen-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Huayou-Cobalt-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Solvay-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Siegfried-Jacob-Metallwerke-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/RETSCH-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/AMG-Graphite-Logo.jpg/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/HANWA-Europe-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/T-B-Electronic-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/BitRaser-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Sachtleben-Technology-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Proses-Makina-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Nickelhuette-Aue-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Agosi-Logo.jpg/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/exhibitors-2026/LogCharge-Logo.jpg/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/WEEECYCLING-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/euragglo-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/FireBox-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Prodecologia-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/ILT-Industrie-luftfiltertechnik-Logo.jpg/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Belec-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/BLUELINE-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Industri-Textil-Job-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/For-Rec-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/AMG-Lithium-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Jacob-Metal-Group-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Electrocycling-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/seLictive-recycling-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/ERI-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Fortum-Battery-Recycling-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Westeria-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Linev-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/E.K.AN-POLYGREEN-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Circu-LI-ION-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Sensoneo-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Siemens-AG-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/ST-BICH-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/CNGR-Silver-Sponsor.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/exhibitors-2026/PRALL-TEC-Logo.jpg/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Eco-Goldex-Inc-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Elemental-Holding-Logo.webp/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/LITech-Logo.png/fit-in/640x9999/filters:no_upscale())

|https://cdn.asp.events/CLIENT_TransGlo_DB55CC41_0052_9F0E_6F42C9E24DA38904/sites/ebmi-expo-global/media/libraries/exhibitors/Loedige-Logo.png/fit-in/640x9999/filters:no_upscale())